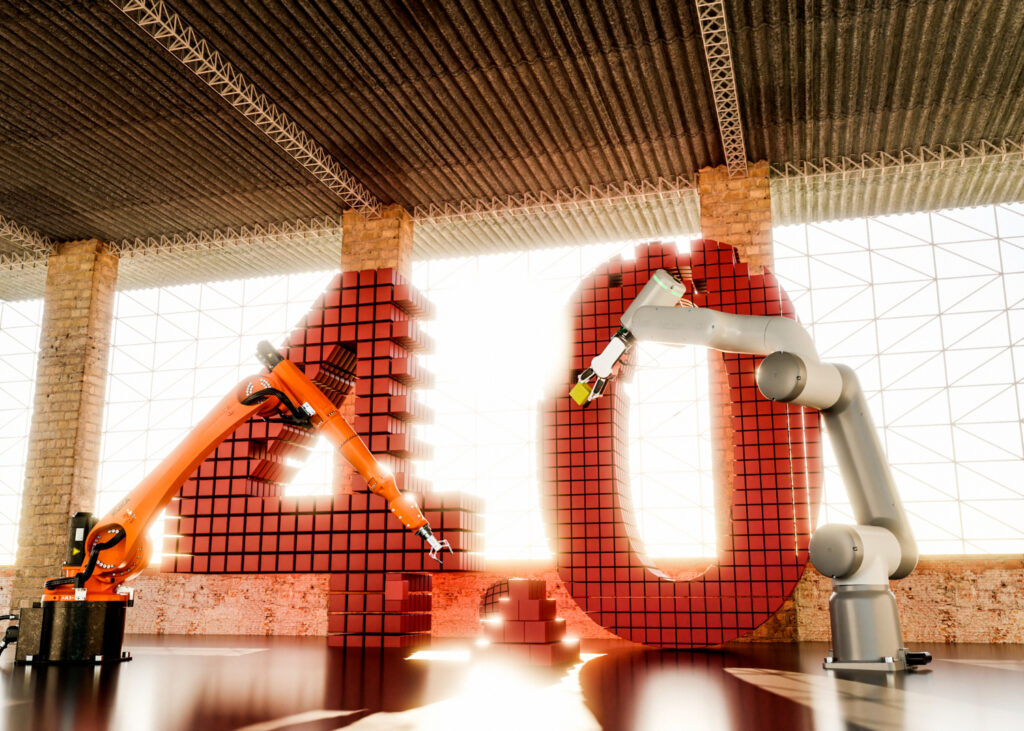

As industries embrace Industry 4.0, the focus is shifting beyond automation and digitalization — toward energy efficiency and sustainability. Modern factories are no longer measured only by production output, but also by how intelligently they manage energy consumption. This is where energy monitoring and optimization play a crucial role.

The Need for Smarter Energy Management

Energy costs often account for a large portion of industrial expenses. Without proper monitoring, inefficiencies such as equipment overuse, power wastage, and load imbalances can silently increase costs. By implementing automated energy monitoring systems, industries gain real-time visibility into where and how energy is used — helping them identify patterns and cut unnecessary consumption.

What Is Energy Monitoring and Optimization?

Energy monitoring involves tracking the usage of electricity, gas, water, and other utilities through sensors and smart meters. Optimization goes a step further by using automation and data analytics to adjust equipment performance for maximum efficiency.

Together, these systems help industries:

Reduce operational costs

Improve equipment performance

Enhance sustainability and meet compliance goals

Predict and prevent energy-related failures

Technologies Behind Smart Energy Systems

The new generation of PLC-based controllers, IoT sensors, and SCADA software enables industries to collect and analyze data at every stage of production. Real-time dashboards and reports give engineers the ability to take immediate corrective action and balance energy loads intelligently.

In advanced setups, AI algorithms automatically adjust machinery speed, lighting, and HVAC systems to maintain optimal energy performance without compromising productivity.

Benefits of Energy Monitoring in Industry 4.0

Operational Transparency – Clear insight into every energy-consuming process.

Cost Savings – Reduced utility bills through efficient power usage.

Sustainability – Lower carbon footprint and environmental impact.

Predictive Maintenance – Detect abnormal power usage before equipment failure.

Continuous Improvement – Data-driven insights that refine processes over time.

Conclusion

The integration of PLC and SCADA has redefined how industries operate. As automation technologies advance, these systems will continue to evolve — bringing smarter, more efficient, and sustainable industrial control for the future.